Essential Takeaways

• Our first Impact Goal is to have one hundred percent of our active and other ingredients in our products Made Traceable with the supplier name and final place of manufacturing publicly available by the end of 2022.

• When it comes to tracing beyond the final place of manufacturing, it becomes very complicated, but getting down to ingredient origin is our ongoing mission.

Spoiler alert: this goal is 100% complete! But our work doesn’t stop there. While we met our goal in 2022, it’s an ongoing process to ensure all newly rolled out products also meet that bar of traceability.

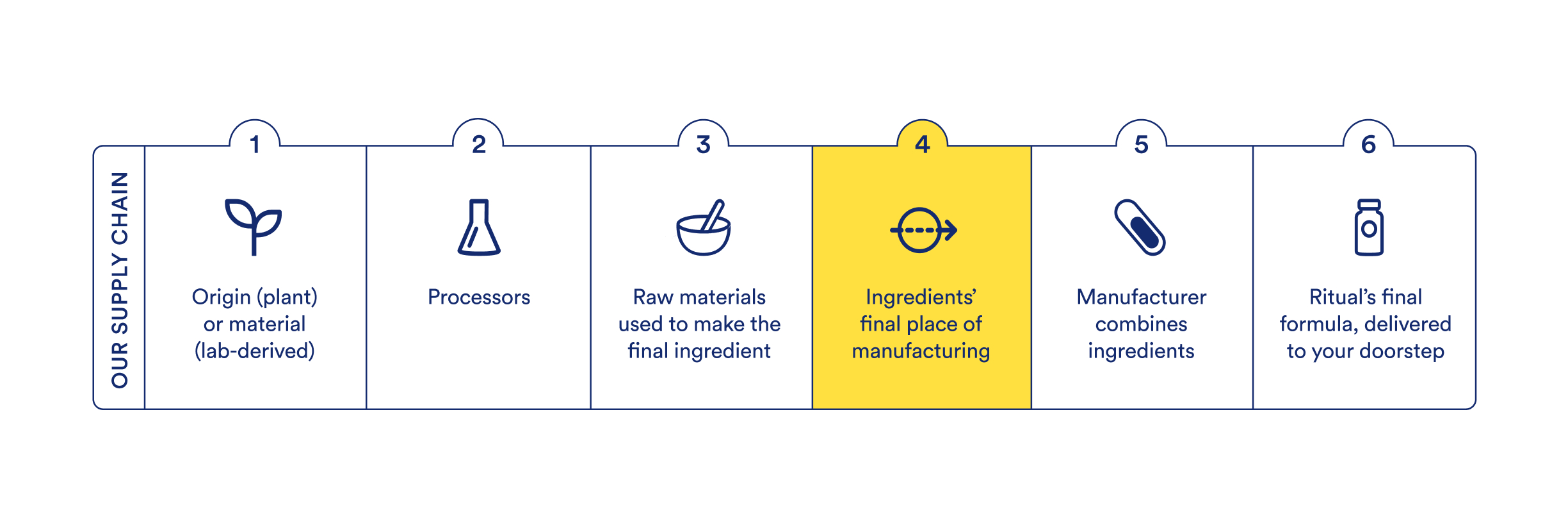

When our Founder & CEO Kat Schneider started Ritual, she had a vision to do things differently, bringing more traceability to the science and sourcing behind the multivitamin. A proof point of our traceable sourcing is one we’ve shared with our customers since 2016: publicly sharing the supplier name and final place of manufacturing for our active and other ingredients. This ingredient mapping is the first part of our Made Traceable® world.

Transparency Starts With Our Suppliers

When we launched three industry-defining impact goals, it should be no surprise that ingredient traceability would be front and center. Our goal is to have one hundred percent of our active and other ingredients Made Traceable® by the end of 2022. This gives you access and insight into who we partner with to formulate our products. We believe in partnering with suppliers who care as much about their supply chains as we do.This transparency is unprecedented in our industry, but for our standards and our curious consumer, we are taking on the challenge.

Ingredients go through varying levels of sourcing and processing facilities, which is why we define “final place of manufacturing” as where the ingredient is tested and finally processed for sale. This location is typically where we receive final certificates of analysis for the ingredients as part of our quality program, the receipts so to speak.